electrical resistance measurement

TQC has provided a common unit for resistance measurement for a variety of

projects. This module provides a cost-effective method of process checking the resistance

value of an integral component in an assembly.

Successful application to date are:

| To verify integrated variable

reluctance speed sensor mounted within an internal combustion turbocharger assembly. |

|

| To verify both diesel and petrol

engine injector harness wiring and injector type. |

| Final resistance value of electric

windings prior to varnish impregnation. |

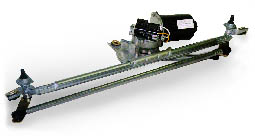

| Final assembly checks on windscreen

wiper motors and harnesses. |

| After final assembly, check the

continuity of headlamps complete with bulbs. |

The unit can be configured to operate over a very

wide range of resistance values, and where necessary be provided with special connection

blocks to directly interface to most types of connectors used on either components or

harnesses. The unit can be connected to external controls, lamps, audible warning devices

and PLC control systems to fully integrate into the production line environment.

|

|

| Windscreen Wiper

Assembly |

Automotive Sender

Assembly |

The test facility consists of a rugged metal enclosure fitted with an intelligent

panel meter, which reads the resistance present at a dedicated interface connector. Four

volt free contacts will determine a pass band on a typical resistance value.

The interface connector is connected to the instrument by 5m of flexible conduit

and the mains supply and volt free contacts are via 20mm gland holes in the rear panel of

the instrument. All connections are via Din terminals at the rear of the unit.

If the component passes the test, the volt free contacts will close; at all other

times they will remain open circuit. The set points are manually adjustable.

The test is performed continuously, hence the

pass condition will only occur if the resistance falls between the high and low set

points. Under normal operating conditions, no resetting of the resistance meter should be

necessary.

measurement & test

equipment capabilities

TQC combines extensive experience with a

modular approach. The best modern data capture methods and proven software techniques are

engineered into your production environment to provide reliable and easily maintainable

measurement or test equipment.

Speed |

|

Noise and

vibration |

Torque |

|

Distance and

rotation |

Voltage |

|

Inductance

and capacitance |

Current |

|

Frequency |

Resistance |

|

Power |

| Flow |

|

Pressure |

| Temperature |

|

Force |

If

you have a current project that you are already looking at, or you

are considering improvements to your production in the near future,

call us and we will be happy to offer our professional advice &

visit you at your site.

Feel free to contact TQC using the links below.

|

TQC Ltd, Hooton Street,

Carlton Road,

Nottingham, NG3 2NJ, United Kingdom

Tel: +44 (0)115 9503561

Fax: +44 (0)115 9484642

E-mail: sales@tqc.co.uk

|

|